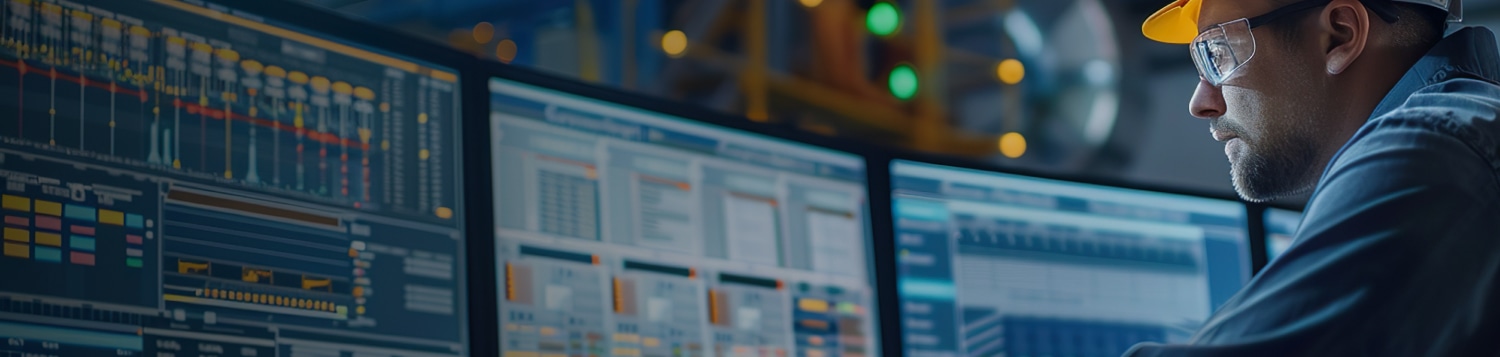

Reliable Monitoring Solutions for Power Generation Assets

In power generation, reliability isn’t optional—it’s mission-critical. Monico delivers proven solutions for engine and generator monitoring in prime power, standby, and distributed generation applications. Whether your assets are on the grid or off it, we help you monitor equipment health, reduce downtime, and gain complete operational awareness in real-time.

From gensets in hospitals and data centers to turbines and backup power at remote facilities, our gateways integrate with leading OEMs and controller protocols, providing a unified, preconfigured platform for smarter performance monitoring.

With Monico’s power generation monitoring, you can:

- Monitor engines, gensets, and switchgear from anywhere

- Capture real-time data for trending, fault diagnostics, and load analysis

- Integrate directly with CAT, Cummins, Kohler, Generac, MTU, and more

- Connect to SCADA, BMS, or cloud-based platforms like AVEVA PI

- Receive instant alerts and notifications via email or SMS

- Streamline maintenance planning and reduce unplanned outages

When uptime is everything, Monico delivers the insight and control needed to keep your power assets online and optimized.

Remote Generator Monitoring Solutions

If a BMS system is not available, then a Monico PLUS Gateway can act as the primary interface if an Ethernet network is available, making remote generator monitoring simple. The Gateway offers a pre-configured virtual color touch screen HMI over the internet. The email server can notify the customer when certain conditions occur and the Virtual HMI is available from anywhere on the network for viewing live data and detailed fault codes. If an Ethernet network is not available or the customer does not want the Generators connected to the BMS, then we can also offer cellular solutions that provide a cost-efficient alternative.

Natural Gas and Diesel Generator Monitoring Solutions

A very common application for Monico Gateways is the monitoring and basic control of natural gas-fueled and diesel-fueled generators. We regularly provide customer interfaces for Caterpillar®, Cummins®, Generac® and MTU® equipment, and the Gateways can also be used to provide data concentration for other devices such as Digital I/O, Analog I/O, Thermocouples, RTD’s, Switchgear and fuel tank level monitoring.

The Gateway can gather electrical information from the Generator Set Controller (GSC) and detailed information from electronic engines. If a mechanical engine is used, then we communicate directly with the GSC to gather complete electrical data and basic engine data. Complete fault code support is available. Gensets with mechanical engines and basic GSCs will provide about 8-10 valuable monitoring parameters plus fault codes. Gensets with more robust GSCs offer very detailed electrical information including line-to-line and line-to-neutral voltages, line currents, and various power calculations. Electronic engines will provide about 50-80 additional parameters of detailed information, and some of the larger gensets will have 4-5 Electronic Control Modules and provide up to about 220 parameters of data for monitoring purposes.

Future-proof your monitoring system

Need live data to keep your power assets online and efficient?

Monico Live provides secure, cloud-based access to real-time equipment performance across your power generation systems. Monitor turbines, engines, switchgear, and more—remotely and reliably. With instant visibility into alarms, trends, and health indicators, Monico Live supports faster diagnostics, optimized maintenance, and reduced downtime across critical generation infrastructure.

- Data collected from a generator provided to a BMS or the IT Management Software through a single interface

- Transfer switches, high resistance ground monitors, circuit breakers and other auxiliary equipment monitored and integrated into the overall monitoring system

- Data collected from both gensets and auxiliary equipment sent to the BMS via BACnet UDP or SNMP, or a virtual HMI can be provided from any browser device on the network

- Available remote Start/Stop functionality for generators with that capability

- Help prevent downtime by monitoring test and exercise periods to detect potential causes of Failure to Start and Failure to Run issues

- Monitoring and data collection on equipment provided to an overall monitoring system to track fuel consumption, power factor, and engine hours

- Improve preventive maintenance efforts by adding analytic capabilities and prevent failures with alarm notifications via Email or SMS

- Virtual HMIs provided for instant data including complete fault code support with text descriptions

- Monitor and collect data from the generators as well as auxiliary equipment such as transfer switches to integrate into your overall monitoring system

- Send all data collected back to the Building Management Systems via BACnet UDP or SNMP or provide a virtual HMI from any browser device on the network

- Use data collected to add an analytic capacity to preventive maintenance programs

- Remote start/stop functionality is available for generators with that capability

FAQs

Frequently Asked Questions

What types of power generation equipment can Monico monitor?

Monico systems support diesel and natural gas generators, engine-driven power modules, turbines, and hybrid power systems. We integrate with major OEMs including CAT®, Cummins®, Kohler®, Generac®, MTU®, and John Deere®, capturing engine and control system data in real time.

Can Monico monitor standby and emergency generators?

Yes. We frequently monitor standby gensets used in hospitals, data centers, and critical infrastructure. Our systems ensure that backup power sources are healthy, tested, and ready to perform when needed.

How does Monico integrate with building and energy management systems?

Monico Gateways output data in protocols like Modbus, BACnet, SNMP, and OPC UA, allowing seamless integration with BMS, SCADA, and energy monitoring systems. We also offer dashboards and alerts via MonicoLive™.

What kind of data can I monitor from my generator?

You can track engine RPM, voltage, frequency, load, fuel consumption, fault codes, runtime, temperature, and more. Our gateways also support freeze-frame diagnostics, data logging, and fault code text descriptions.

Can Monico solutions help reduce unplanned downtime?

Yes. With real-time fault monitoring, custom alarm thresholds, and preventive diagnostics, our customers reduce unscheduled outages, optimize service schedules, and increase equipment lifespan.

Do Monico solutions support remote access and control?

Absolutely. With MonicoLive™ or embedded Virtual HMI, you can monitor genset performance remotely, receive alerts, and even initiate remote start/stop for generator exercises or emergency response.

Monitoring Products