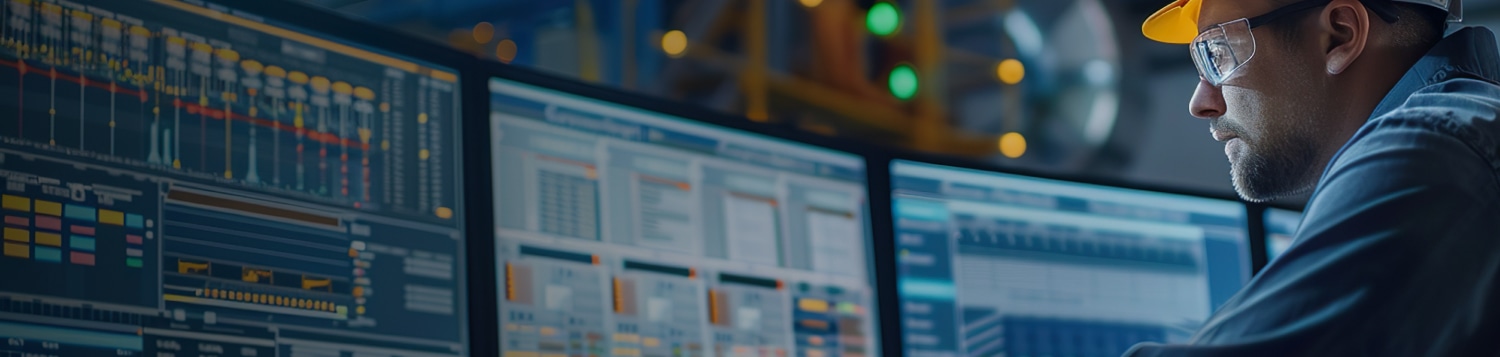

Marine-Grade Monitoring Solutions for Propulsion, Power & Performance

In power generation, reliability isn’t optional—it’s mission-critical. Monico Monitoring delivers proven solutions for engine and generator monitoring. Whether you’re managing offshore supply vessels, crew boats, or power generation systems below deck, Monico provides marine engine monitoring solutions built for reliability, integration, and real-time visibility. Our Gateways deliver actionable data to marine automation systems, wheelhouse HMIs, and PLC-based alarm systems—helping ship operators reduce downtime, improve efficiency, and maintain compliance.

With support for engines, generators, thrusters, z-drives, and auxiliary systems, Monico bridges the gap between onboard machinery and the control systems that keep vessels running smoothly.

With Monico’s marine monitoring systems, you can:

- Monitor propulsion engines, power generation, and auxiliary systems

- Transmit real-time fault codes, alarms, and performance data to the wheelhouse

- Interface with Woodward controllers, switchgear, and PLCs—no extra modules needed

- View live equipment data on marine-grade HMIs

- Reduce unplanned downtime through preventive maintenance insight

- Preconfigure systems for seamless integration into new or existing automation systems

Built rugged for marine environments and backed by proven installations across offshore and commercial fleets, Monico delivers the insight you need—wherever your vessel goes.

Future-proof your monitoring system

Need real-time visibility into your vessel systems?

MonicoLive gives marine operators secure, cloud-based access to critical equipment data—no matter where the vessel is. Monitor engine performance, alarms, and system trends from shore to support remote diagnostics, reduce unplanned downtime, and keep operations on schedule. From individual vessels to full fleets, MonicoLive delivers the insight and control to make informed decisions across your marine assets.

Monitoring within Marine Automation Systems

Marine automation systems provide a ship with one central way to control and monitor its equipment and operations. This system requires data acquisition from multiple pieces of equipment on a ship and the integration of that data into the automation system. Doing this effectively can save costs, energy and materials. Monico has worked within many marine automation systems and marine control systems and can collect, convert and provide data as needed.

Monitoring for Propulsion

- Bow thrusters, fire pumps, z-drives and other auxiliary equipment that can be incorporated into an overall marine control system

- Provide engine and associated equipment parameters to the ship’s alarm system, the marine automation system, and wheelhouse

- Acquired data supports and improves preventive maintenance programs

Monitoring for Power Generation

- Monitoring and integrating data acquired through the Gateways reduces maintenance costs, improves efficiency and reduces downtime

- Data collected supports and improves preventive maintenance programs

- Engine and generator data are provided to the wheelhouse and integrated into overall marine monitoring system

- Engine parameters and alerts and alarms are provided to the ship’s marine automation system as well as the ship’s alarm system

Monitoring for Offshore Supply

- Bow thrusters, z-drives, fire pumps and other auxiliary equipment can be monitored and integrated into a marine monitoring systems

- Parameters from engines and associated equipment are provided to a ship’s alarm system, automation system and the wheelhouse

- Monitoring helps improve overall maintenance programs, which prevent downtime and reduce costs

Specifics on Marine Engine Monitoring Systems

Monico Gateways are used extensively in the marine markets with a heavy installed base on offshore crew and supply boats. Most generators in the marine market are controlled by Woodward controllers, so they do not have EMCP style GSCs. Genset data is brought in via the dedicated port, which leaves (2) RS-232 ports, (1) RS-485 port, and (1) Ethernet port for gathering data from other system components such as switchgear or Woodward controllers. Each serial port can communicate via one protocol independently, either master or slave. The Ethernet port can communicate via four protocols simultaneously.

In marine communication applications, grounding is particularly important. In most cases, the negative of the engine battery is grounded to the hull which is effective. However, there are times when ship builders choose to isolate the engines from the hull, which causes communications issues. In these cases, we use an isolated repeater to isolate our Gateways from the engine and reduce the chance of ground loops. An added benefit of the isolated repeater is the ability to remotely mount the Gateway up to several thousand feet from the engine. Monico commonly installs color touch screen HMIs in the wheelhouse for a single common marine engine monitoring interface which provides space efficiency in crowded environments.

Most of these types of vessels have automated marine control systems with PLCs. So, the Gateway acts as a data concentrator for engines, generators, thrusters, auxiliary engines, switchgear and other controllers. We then provide usable data to the PLC-based control/alarm system and for display on the HMIs in the wheelhouse. Our Gateways are compatible with Siemens, GE Fanuc, Allen Bradley, and Omron PLCs without need for additional modules or drivers. HMIs are also used as a stand-alone display system. If a PLC-based control/alarm system does not exist, then a Gateway PLUS and HMI can be used to provide a stand-alone monitoring system.

Learn More:

FAQs

Frequently Asked Questions

What types of marine equipment can Monico monitor?

Monico supports monitoring for main propulsion engines, gensets, thrusters, z-drives, fire pumps, and auxiliary equipment. We work with Woodward controllers, as well as directly with ECMs and switchgear, to provide a complete monitoring solution for vessels of all sizes.

Do you support remote access or wheelhouse display screens?

Absolutely. We offer marine-grade HMIs that can be installed in the wheelhouse to provide a consolidated view of all engine and equipment data. Additionally, data can be accessed remotely using MonicoLive™ or web-based interfaces depending on network architecture.

What makes Monico’s Gateways ideal for marine applications?

Our systems are preconfigured, protocol-flexible, and compatible with the most common PLCs used in marine control environments. With support for multiple simultaneous protocols, we consolidate data from engines, generators, and auxiliary equipment into one stream—reducing hardware, simplifying integration, and enhancing visibility.

Can Monico systems integrate with my marine automation system?

Yes. Our Gateways can communicate over multiple protocols—Modbus, Ethernet/IP, Siemens S7, GE SRTP, and more—to interface directly with PLC-based automation and alarm systems. We also offer standalone HMI solutions when a centralized control system isn’t available.

How is marine monitoring different from land-based engine monitoring?

Marine applications often involve more complex grounding challenges and tightly integrated control systems. Our experience with hull-isolated grounding, signal repeaters, and space-constrained wheelhouse displays ensures communication integrity and operational simplicity onboard.

Can I use Monico’s system as a standalone monitoring solution?

Yes. If your vessel doesn’t have a PLC-based control system, our Gateway PLUS and optional touchscreen HMI can be used to create a fully standalone marine engine monitoring system—ideal for smaller vessels or retrofits.