Real-Time Visibility. Proven Durability. Smarter Fleet Decisions.

In mining, uptime is everything. Monico delivers rugged, field-proven solutions that give you real-time insight into your most valuable equipment, from haul trucks and loaders to dozers and drills.

Our preconfigured systems collect high-resolution data directly from engines, ECMs, and controllers—translating proprietary protocols like CAT® CDL and J1939 into actionable intelligence. Whether you’re managing remote mine sites or optimizing utilization across a multimillion-dollar fleet, Monico helps you make faster, smarter, data-driven decisions.

With Monico’s mining monitoring solutions, you can:

- Capture high-resolution, real-time data from engines, ECMs, and controllers

- Translate proprietary protocols like CAT CDL and J1939 into usable formats

- Stream data to SCADA, AVEVA PI, MonicoLive™, or your existing IIoT platform

- Monitor fault codes, KPIs, and diagnostics from anywhere—on or off site

- Deploy rugged, IP67-rated gateways built for shock, vibration, and dust-heavy environments

- Simplify implementation with preconfigured setups and intuitive dashboards

Whether you’re coordinating remote operations or extending the life of high-value assets, Monico bridges the gap between machine data and operational intelligence—empowering mining teams to reduce downtime, prevent failures, and boost productivity.

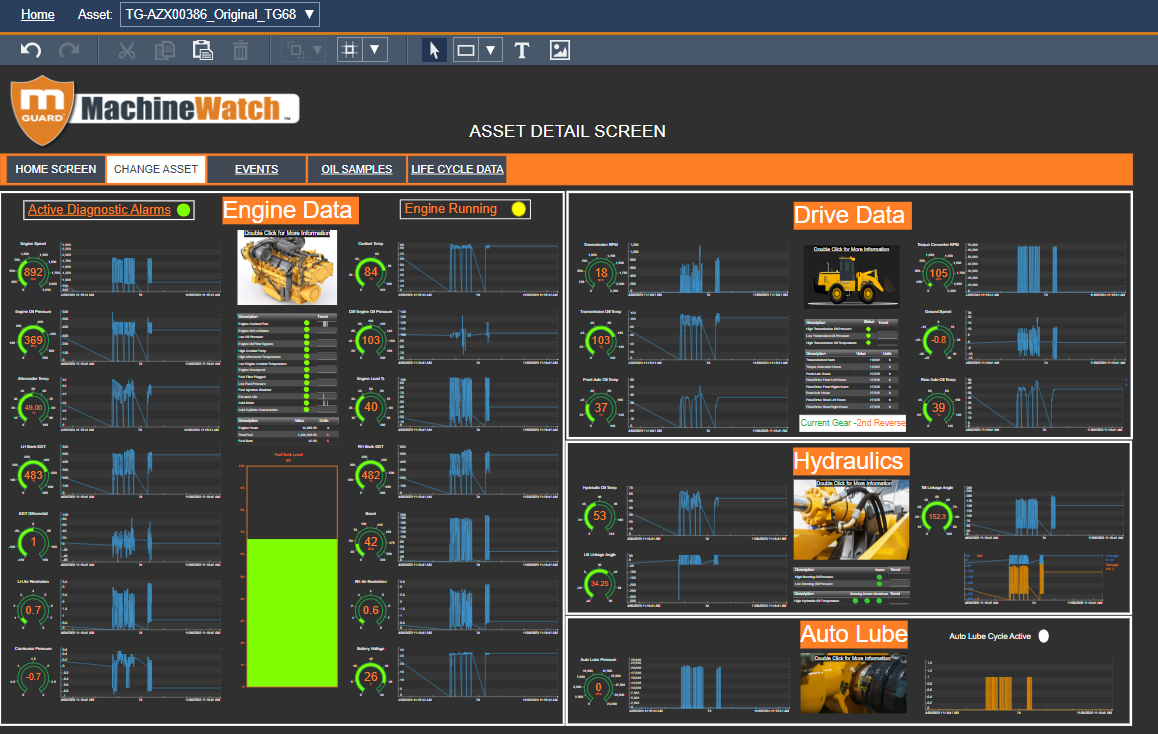

mGuard® MachineWatch

Ready for smarter machine protection?

Protect Critical Equipment. Predict Failures. Maximize Uptime.

mGuard® MachineWatch brings predictive condition monitoring to rotating and reciprocating equipment. With built-in edge diagnostics, real-time fault detection, and seamless integration into your existing monitoring environment, Machine Watch turns vibration, temperature, and performance data into early warning insights. Improve reliability, reduce downtime, and extend machine life — all without the complexity.

Turn Data into Uptime

Advanced Analytics for Mining Assets

Optimize Reliability. Reduce Unplanned Downtime. Make Data-Driven Decisions.

Mining operations run on tight margins and tougher conditions — there’s no room for unexpected failures. Monico’s advanced analytics platform transforms raw equipment data into actionable intelligence, empowering mine operators to make faster, smarter maintenance decisions.

From mobile haul trucks and drills to fixed processing equipment, our edge-enabled solutions detect anomalies, trend performance, and trigger early alerts before issues become downtime. With Monico’s real-time analytics, you get more than data — you get a competitive edge.

Remote Equipment Monitoring for Mining Operations

Modern mining operations depend on more than heavy equipment—they depend on real-time data to keep that equipment productive, safe, and cost-effective. With haul trucks, loaders, and dozers costing $3M–$5M each to acquire and maintain, it is critically important to monitor and manage every nuance of their operation.

While most operations already have systems for production management and maintenance tracking, Monico enables the next step: turning machine-generated data into operational intelligence. Whether it’s detecting excessive brake temperatures or spotting early signs of engine wear, our solutions help teams act before failures happen—not after.

As mining embraces technologies like IIoT, machine learning, and predictive analytics, Monico provides the tools and expertise to make those technologies work—without the complexity.

Key Data Capabilities:

- Real-Time Data Acquisition: Stream live data from engines, ECMs, and onboard systems to monitor equipment health and performance in real time.

- Protocol Conversion: Read and translate proprietary protocols like CAT® CDL and J1939 into standard formats for seamless system integration.

- System Integration: Transmit structured data to HMIs, PLCs, SCADA, or IIoT platforms to support centralized monitoring and control.

- Edge & Cloud Analytics: Enable advanced diagnostics and trend analysis at the edge or in the cloud using Monico’s mCore® and MonicoLive™.

- Interactive Dashboards: Visualize equipment status, KPIs, and alerts through browser-based dashboards designed for field and operations teams.

- Data Value Optimization: Identify high-impact data streams with support from Monico SMEs to determine how and what data is valuable to their organization’s needs

With Monico’s rugged gateways and remote monitoring solutions, mining teams can boost equipment performance and reliability, improve utilization and extend asset life, increase productivity by reducing unplanned stoppages, enhance safety through predictive alerts and real-time visibility, and optimize operations by aligning machine data with business goals. Monico serves as the bridge between your equipment and the intelligence needed to operate it more efficiently.

Learn More:

Download Datasheet

Remote Monitoring – Mining and Caterpillar

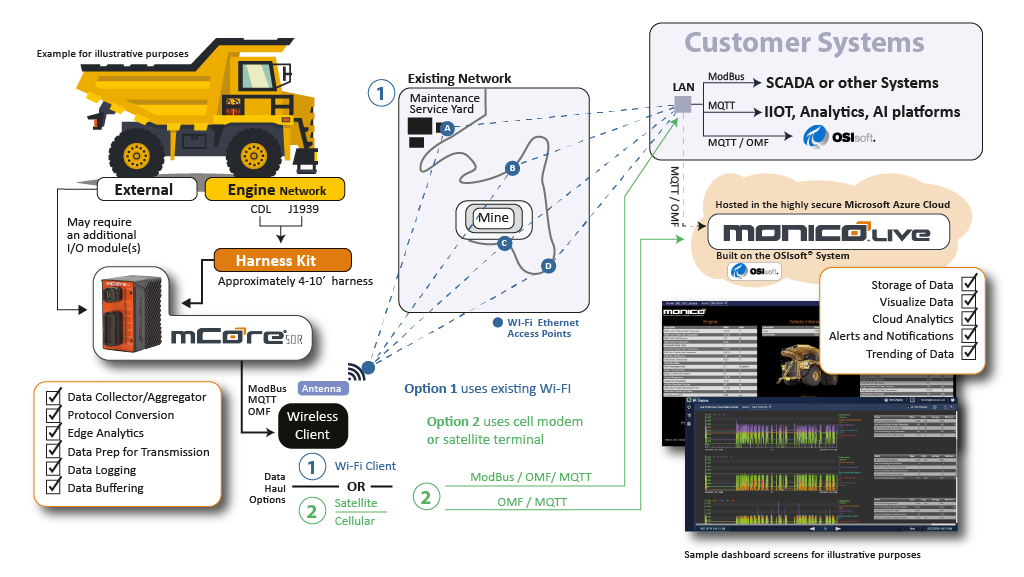

mCore®SDR for Mining Asset Data Acquisition

Monico’s mCore®SDR is the next evolution in asset data acquisition for the mining industry. Built on years of field-proven success with our Gateway technology, mCore®SDR is faster, more rugged, and purpose-built for harsh industrial environments—making it ideal for haul trucks, loaders, dozers, and other critical mining equipment.

With IP67/IP66 certifications, Class I Div. II Hazardous Location approval, and shock/vibration ratings up to 25G, mCore®SDR is designed to survive and perform in the dust, heat, and vibration of active mines, quarries, and construction sites. Backed by Monico’s expert technical support, it delivers dependable performance where other systems fall short.

It’s Your Machine. Your Data. Your Way.™

Too many OEM systems offer limited access to data or route it back to the manufacturer—restricting your visibility. Monico does it differently.

mCore®SDR includes a CAT® CDL port and dual CAN ports (e.g., J1939), allowing direct integration with engine control modules (ECMs) across your fleet. It provides high-resolution, real-time streaming data—comparable to OEM systems like ProductLink™ and VIMS®—but with greater flexibility, broader system compatibility, and a significantly lower total cost.

Monico offers the high-quality data you expect from an OEM, but with the flexibility and innovation you’d expect from a custom provider, alongside the quality and support you’ve come to expect from Monico. We communicate directly with third-party or aftermarket hardware, allowing custom machine and data integration designed to meet your fleet monitoring needs. With available support for the most modern data analytics systems.

Monico bridges the gap between your mining equipment and the operational insights made possible through advanced analytics. By leveraging live-streaming data from engines, ECMs, and control systems, we help mining operations transform raw machine data into actionable intelligence—improving visibility into equipment performance, utilization, productivity, and health.

Our Gateways are preconfigured to collect and transmit high-resolution data from mining assets and seamlessly interface with broader monitoring infrastructure. When properly integrated, these systems can route fault codes, event data, and diagnostic alerts to centralized control platforms—providing early warning of potential shutdowns or failures. The result is a more proactive and effective mine monitoring strategy that supports higher equipment availability, safer operations, and optimized asset performance.

Key Highlights

- Preconfigured & Ready to Deploy: No custom coding required—just plug and monitor

- Multi-Protocol Support: Read and transmit CAT® CDL, J1939, and other industrial protocols

- Browser-Based UI: View live data, configure logs, and access diagnostics from any device

- Edge Aggregation: Consolidate multiple equipment data streams into a single access point

- Ruggedized Hardware: Shock-tested, waterproof, and dustproof for extreme mining conditions

- IIoT Ready: Supports MQTT, OMF, and other modern data transmission standards

Learn More:

MonicoLive™ for Remote Mining Equipment Monitoring

MonicoLive™ is a secure, web-based platform designed to provide real-time remote monitoring, data analytics, and visualization for critical mining assets. Accessible from any internet-enabled browser, it enables operators, maintenance teams, and decision-makers to monitor equipment performance and diagnostics from anywhere in the world.

Built on the industry-trusted AVEVA PI System and hosted in the Microsoft® Azure cloud, MonicoLive™ delivers a scalable and resilient solution for mines seeking to centralize and act on equipment data—without building their own infrastructure.

Whether you’re using MonicoLive™ as your primary monitoring platform or alongside existing AVEVA PI deployments, the system provides immediate access to meaningful insights through:

- Real-time data streaming and alerting

- Custom dashboards and visualizations

- Advanced analytics and trend detection

- Secure data storage and historian functionality

- Seamless integration with IIoT, SCADA, HMI, and other control systems

An Accelerated Path to Insights

For mining operators without an existing remote monitoring solution, MonicoLive™ offers a fast, low-overhead path to digital transformation. The platform is fully preconfigured by Monico’s subject matter experts and supports real-time data ingestion from mCore®SDR gateways and other field devices.

Captured data can be viewed in MonicoLive™, routed to other business systems, or integrated with enterprise-level AVEVA PI solutions—enabling your teams to start making data-driven decisions immediately.

MonicoLive Highlights:

- Preconfigured & Ready to Deploy: Gateways and dashboards come fully set up—no coding required

- Real-Time Alerts & Notifications: Get automated warnings for faults, shutdowns, and critical events

- Data Historian & Analytics: Store, trend, and analyze equipment performance over time

- Readable Fault Codes & Diagnostics: Simplify troubleshooting with clear, actionable insights

- Expert-Built Visualizations: Custom dashboards tailored to your equipment, workflow, and team

Learn More:

Preconfigured Solutions for Rapid Deployment

Monico delivers preconfigured and integration-ready monitoring solutions tailored for the mining industry. Whether you’re connecting to an existing mine monitoring system—such as AVEVA PI—or deploying Monico’s MonicoLive™ cloud platform, our solutions are built to streamline installation, reduce setup time, and deliver immediate value.

When you purchase a Monico Gateway, you’re not just buying hardware—you’re getting a system that’s ready to perform. Devices are preconfigured using Monico’s extensive library of proven data maps, with full support from our technical team to guide wiring, connections, and system integration. It’s as close to plug-and-play as mining gets.

What’s Included with a Monico Gateway:

- Data Scaling & Tag Mapping: Predefined mappings aligned to your equipment and use case

- Fault Code Translation: Enumerate fault codes into meaningful messages with severity states

- State Monitoring: Identify fault priorities (e.g., low vs. high) and determine if a fault is active

- Custom Tag Support: Map and monitor OEM-specific or user-defined data points

- Extensive Prebuilt Libraries: Accelerate configuration with validated templates for mining equipment

Easy Connection with Prebuilt Harness Kits

To simplify physical installation, Monico offers prebuilt wiring and harness kits for common industrial connections—whether you’re using RS-485, Deutsch connectors, or other standard formats. These kits reduce install time and help system integrators avoid compatibility issues on site.

MonicoLive Dashboard Configurations & Visualizations

For customers using MonicoLive™, we provide ready-to-use dashboards and visualizations tailored to your operational needs. Our team works with you to define layout, metrics, and alerting logic—from bar charts and gauges to trend graphs and data tables.

Users can also build custom views, save configurations, and create ad hoc screens to suit evolving requirements—giving your teams the flexibility to explore and act on equipment data in real time.

Read More:

Why Monico

Key Advantages that Set Monico Apart in the Mining Industry

Full ownership of your equipment data

In mining, visibility is critical, and so is control. Monico ensures that all data collected from your haul trucks, dozers, loaders, and other equipment stays securely in your hands. No manufacturer lock-in, no data black boxes—just direct access to real-time insights that drive uptime, safety, and ROI.

Preconfigured for harsh mining environments

Every Monico system ships ready to deploy; preloaded with proven data maps, fault logic, and tag configurations for common mining assets. Whether you’re connecting to CAT® CDL, J1939, or custom OEM protocols, our plug-and-play approach eliminates guesswork and accelerates installation.

Built for real-world mining teams

Our dashboards and interfaces are designed for the people using them, from field techs to reliability engineers. With intuitive browser-based tools, users can view fault codes, performance KPIs, and equipment trends without needing specialized software or training.

Works across your entire fleet

Mines run mixed fleets, and Monico is built for that reality. Our gateways support multiple industrial protocols and integrate with CAT®, Komatsu, Cummins®, MTU®, John Deere®, and more. Whether you’re feeding data to SCADA, AVEVA PI, or MonicoLive™, our systems make integration simple—no custom coding required.

Monitoring Products

Mining Engine Monitoring Products

FAQs

Frequently Asked Questions

What types of mining equipment can Monico monitor?

Monico supports remote monitoring of haul trucks, loaders, dozers, gensets, and more—particularly those powered by CAT®, Cummins®, Komatsu, Liebherr, MTU®, or John Deere® engines. Our Gateways connect directly to ECMs using CDL, J1939, and other industrial protocols.

What makes Monico solutions ideal for the mining environment?

Our mCore®SDR Gateways are built for the field. They’re waterproof, dustproof, shock- and vibration-tested to 25G, and certified for hazardous locations (Class I Div. II). They’re built to survive—and thrive—in mines, quarries, and remote sites.

Can Monico help us integrate with AVEVA PI or other existing platforms?

Yes. We support native integration with AVEVA PI, SCADA systems, HMI dashboards, and IIoT platforms via MQTT, OMF, and other protocols. We also offer MonicoLive™ for teams without an existing infrastructure.

How is Monico’s data different from what OEM systems provide?

Monico offers real-time streaming data (not delayed snapshots), full access to raw machine parameters, and advanced features like freeze frame diagnostics, data aggregation, and custom PGN decoding. It’s your machine, your data, your way.

What are the benefits of remote monitoring for mining operations?

Remote monitoring reduces unnecessary site visits, increases asset uptime, and allows teams to detect issues before they become failures. With Monico, you can view real-time trends, set custom alerts, and perform analytics to improve maintenance planning and equipment utilization.

Do I need to configure everything myself?

No. All Monico systems are preconfigured, and we offer prebuilt data maps, wiring kits, and dashboards. For system integrators, this greatly reduces setup time and complexity—making installation nearly plug-and-play.