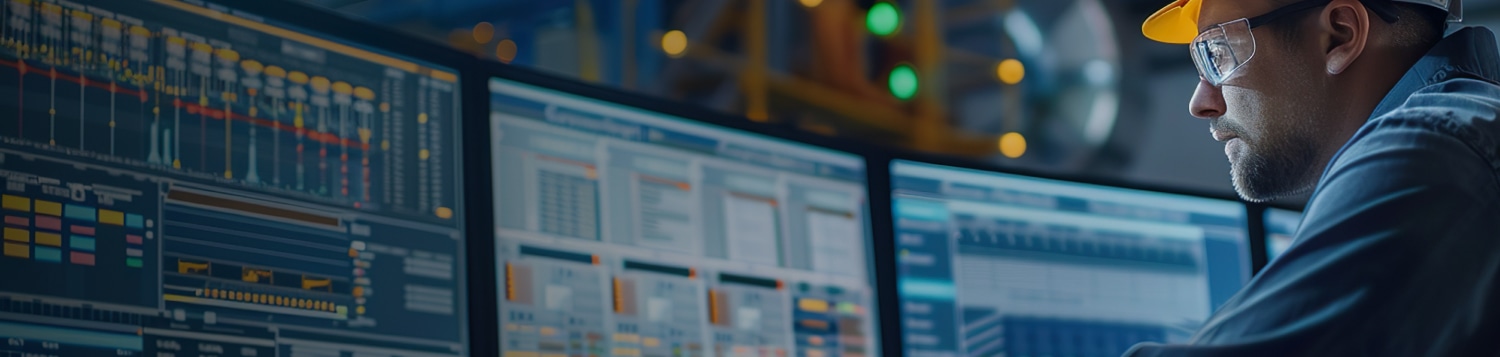

WHAT are hmi systems?

Remote Monitoring and Protocol Converting with Monico HMIs

A pre-configured solution that provides a communications interface to the Caterpillar® line of Industrial Engines and Generator Sets via different protocols and data maps.

Each Gateway HMI is a protocol converter and a full featured HMI that provides direct access to engine monitoring parameters from industrial equipment via many different protocols and memory map formats. The HMIs offer all the same features of the Gateways™ with the addition of an operator interface.

Benefits & Features

- Pre-configured solutions with over 400 data registers

- UL 1604 Class I Division II Approval

- Outdoor rated with UV protection

- Built-In Web Server

- SMTP/SMS Mail Server

- Real-Time Data Logging via Compact Flash (2 GB Max)

- Full-featured Touch Screen with full Graphics capability

- Available in 8, 10 and 15 inch screens

Download Datasheet →

J1939 Gateway HMI

A protocol converter and a full featured HMI that provides direct access to engine monitoring parameters from industrial equipment via many different protocols and memory map formats. The HMI offers all the same features of the J1939 Gateway™ with the addition of an operator interface.

The J1939 Gateway™ HMI (Human Machine Interface) is a plug & play protocol converter and a full featured HMI that provides direct access to engine monitoring parameters from industrial equipment via many different protocols and memory map formats. The HMI offers all the same features of the J1939 Gateway™ with the addition of a local operator interface. It is used in applications where engine data needs to be displayed for local users and operators in addition to being accessed from a PLC or SCADA system. No intermediate devices are needed and little or no setup is required.

Whether the environment you need to interface with is in a factory or a remote location, Monico can configure our HMIs to give you an easy to use operator interface.

More Than a J1939 HMI Protocol Converter

As with all of our products, this HMI acts as much more than just a protocol converter. It allows for an easy way to assess and control what is occurring with various pieces of equipment in your industrial system. And with features that include a built-in web server for access to your equipment from any location with internet access and a SMTP/SMS mail server for email and text alerts, our HMI lets you monitor your equipment remotely.

In addition to J1939 protocol conversion and the ability to act as a CAN bus remote HMI, the J1939 Gateway HMI also translates fault codes into text descriptions and can integrate your engine or genset as well as supporting equipment into an overall monitoring system. Our HMI screens provide a simple way for you to do all of this, as well as interact with your system. We can assist you regardless of what industrial sector you are in, the machinery combination you have and what protocols you are communicating with.

Monico’s HMI units have extra bright backlighting for easy viewing outdoors and are UV protected. All of our HMI products are approved for hazardous locations installations under UL1604. Other features such as our available pre-configured solutions for over 400 data registers, a built-in web server and an AMTP/SMS server, real time data logging and a full featured touch screen with graphics capability make our HMIs easy to install and use as well as very powerful.

There is no better product than our J1939 Gateway HMI for communicating over SAE J1939 and CAN bus when you want the added benefit of a local touch screen operator interface. Monico’s engineers and technical support specialists have spent extensive time working with customers in need of a remote CAN bus remote HMI, J1939 HMI protocol converter, SAE J1939 communication, overall engine or genset monitoring and help integrating equipment into an overall monitoring system.

Specifics on the J1939 Gateway HMI

Input

- Two-Wire Data Link

- Concentrate data from other devices using multiple protocols

Host Interfaces

- Modbus RTU & TCP/IP via Serial and Ethernet

- PLC protocols including Allen Bradley, GE Fanuc, Siemens, BACnet and many more

- Same capabilities as the J1939 Gateway with the addition of a Color TFT Touch Screen HMI

CDL Gateway HMI

A protocol converter and a full featured HMI that provides direct access to engine monitoring parameters from Caterpillar® equipment via many different protocols and memory map formats. The HMI offers all the same features of the CDL Gateway™ with the addition of an operator interface.

CDL Gateway HMI as a Caterpillar® HMI Option

The CDL Gateway™ HMI (Human Machine Interface) is a full featured HMI that provides direct access to engine monitoring parameters from Caterpillar® equipment. This product works as a Caterpillar® HMI solution, and communicates over many different protocols and memory map formats. The HMI offers all the same features as the CDL Gateway™ with the addition of an operator interface. It is used in applications where engine data needs to be displayed for local users and operators in addition to being accessed from a PLC or SCADA system. No intermediate devices are needed and little or no setup is required.

This HMI provides engine data, diagnostics, and event codes including text descriptions directly from the engine network into PLCs such as Allen Bradley, GE, or Siemens, with little to no programming being required with no intermediate devices.

As with all products in the CDL Gateway™ line, the HMI can be used to directly interface with popular generator sets like the EMCP II and EMCP II+, popular Gas Industrial Engines such as the G3600 and G3500 as well as the new GCM34. Engine data can be provided directly into Allen-Bradley, GE Fanuc, and Siemens PLC’s with virtually no programming required. The CDL Gateway™ and its line of HMIs eliminate the need for the CCM Module, the PL1000E, and the ProSoft card needed to convert Modbus into Allen-Bradley PLC’s.

Monico’s Caterpillar® HMI Solutions

The HMIs have double the backlighting of indoor units for easy viewing outdoors and in bright sunlight, are outdoor rated with UV protection and have a full-feature touch screen with complete graphics capability. All of our HMI products are approved for hazardous locations installations under UL1604.

This HMI is a very powerful device that can communicate in up to seven simultaneous protocols over four physical ports. It functions as an operator interface for engine diagnostic codes, text descriptions of fault codes and other critical maintenance information. The products; outdoor rating allows it to function as the system-wide operator interface for not just engine data, but also information from the system PLC, station PLC and other controller systems.

Caterpillar® Remote HMI Option

Many of our customers have their equipment in remote locations, and viewing an HMI remotely is a huge asset when diagnosing problems and troubleshooting. This HMI’s built-in web server, a SMTP/SMS mail server let you monitor remotely. With just internet access, you can access your HMI from anywhere, make adjustments and diagnose problems. Not only does this make you more efficient, it allows you to know what technicians and equipment will be needed without multiple trips to visit your equipment on-site.

CAT® HMI SCADA Option

The CDL Gateway HMI is designed to communicate over CAT® Data Link and can provide the data collected from your SCADA System so that it can be accessed locally. Many SCADA Systems act as a central monitoring system for an entire site, but getting text descriptions of fault codes and other information from Caterpillar® equipment can require multiple steps and equipment as well as the need to access the operations and maintenance manual to translate the codes yourself. Our CDL Gateway HMI does that in one easy step and makes integrating CAT® equipment into your SCADA systems simple.

All of these features, combined with the abilities of our top-notch technical support staff, make Monico’s CDL Gateway HMI the best solution available for Caterpillar HMI needs and Caterpillar® remote HMI solutions.

Available Host Interfaces

- Modbus RTU & TCP/IP via Serial and Ethernet

- PLC protocols including Allen Bradley, GE Fanuc, Siemens, BACnet and many more.

Available Pre-Configured Versions

- Allen Bradley Control Logix, SLC 500 and MicroLogix

- Siemens S7/S5 via PPI, MPI and TCP/IP

- GE 9030 and VersaMAX

- Modbus RTU and TCP/IP

- BACnet MSTP and UDP/IP

In addition to the preconfigured versions, we support many other protocols including:

- CANOpen

- DeviceNet

- Ethernet IP

- Garmin NMEA 0183

- Honeywell

- IDEC

- Koyo

- Mitsubishi

- Omron

- Profibus

- Schneider

- Telemechanique

CPC Gateway HMI

A custom HMI protocol converter and a full featured HMI that provides direct access to engine monitoring parameters from industrial equipment via many different protocols and memory map formats. The HMI offers all the same features of the CPC Gateway™ with the addition of an operator interface.

A Custom Remote HMI

The CPC Gateway™ HMI is an extremely flexible protocol converter and a full featured HMI that provides direct access to engine monitoring parameters from industrial equipment through many different protocols and memory map formats. The HMI offers all the same features of the CPC Gateway™ with the addition of an operator interface. It is used in applications where engine data needs to be displayed for local users and operators in addition to being accessed from a PLC or SCADA system. No intermediate devices are needed and little or no setup is required.

Each CPC Gateway HMI is customizable with Monico’s free software, MonicoView II™, allowing customers to get specific data to fit their needs, and the units have extra bright backlighting for easy viewing outdoors and are UV protected. All of our HMI products are approved for hazardous locations installations under UL1604. This unit will act as a custom HMI protocol converter, and a lot more.

Our HMI as a Custom HMI & Protocol Converter

As with all of our products, this one is a lot more than a simple protocol converter. It can be used to collect information from a myriad of devices that use multiple protocols over multiple ports and put all the information in a common format.

This HMI has a full-featured touch screen with complete graphics capability and comes preconfigured with over 400 data registers. It has a built-In web server allowing you access to your system from any location with internet availability and a SMTP/SMS Mail Server for text and email alerts on alarms and shut downs sent to your phone. Real-time data logging through a Compact Flash card lets you record and report equipment data and store that data long-term.

An HMI SCADA Solution

The CPC Gateway HMI can also provide the collected data from an engine, genset or other equipment to your SCADA System so that it can be accessed both locally and remotely. Many SCADA Systems act as a central monitoring system for an entire site, but getting text descriptions of fault codes and other information can require multiple steps and equipment. Our CPC Gateway HMI does that in one easy step and makes integrating industrial equipment into your SCADA systems simple.

Specifics on the CPC Gateway HMI

Input

- Two-Wire Data Link

- Concentrate data from other devices using multiple protocols

Host Interfaces

- Modbus RTU & TCP/IP via Serial and Ethernet

- PLC protocols including Allen Bradley, GE Fanuc, Siemens, BACnet and many more

- Same capabilities as the CDL Gateway with the addition of a Color TFT Touch Screen HMI

Installation

- Mount the HMI in a panel near the Engine

- Connect the Data Link to the Gateway

- Supply 24 VDC power to the Gateway

- Display data on the HMI screen in Graphical form

Why Monico

Key advantages that set us apart

Your Data is Yours

Your data is securely collected and stored, always remaining under your control, so you can make informed decisions without concerns about data accessibility or third-party restrictions. We’re here to empower you with the insights you need, not limit how you use your data.

Preconfigured, No Coding Required

Our solutions come preconfigured and ready to deploy without the need for complex coding or development. This plug-and-play approach gets you up and running faster, no coding or data analysis required.

Modern Intuitive Platform

Our platform is designed with you in mind, combining modern functionality with an intuitive interface that simplifies data monitoring and visualization. With Monico, you’ll experience an easy-to-navigate system that makes it simple to access, interpret, and act on your data.

OEM-Agnostic, Multi-Protocol Support

Our gateways are preconfigured for your specific equipment and work seamlessly with most major industrial OEMs. With broad protocol support, they easily integrate into mixed fleets—no custom coding or complex setup required.

EASY AS 1,2,3

The Shortest Path to Real-Time

Actionable Intelligence™

1

Schedule a Demo

We’ll walk you through the process and share examples grounded in real data. No big sales pitch. We’ll discuss the problems you’re trying to solve, identify your needs and address your questions about ROI, security, the implementation process, and more.

2

Let Us Configure Your Solution

We won’t just sell you a gateway and wish you luck. Our powerful solutions are simplified for each customer by being pre-configured, down to the serial number of each asset. You’ll easily access data and gain insights from day one, without struggling with siloed data or differing protocols.

3

Count On Us for Support

Our job isn’t done until implementation is successful and you’re getting data exactly the way you want it, where you want it. We’ll provide installation, training and support. In addition, our online resource library is available 24/7.

FAQs

Frequently Asked Questions

What is a Monico HMI system?

A Monico HMI (Human Machine Interface) system is a combined protocol converter and touchscreen interface that allows operators to view and interact with real-time equipment data. It connects directly to industrial engines, gensets, and controllers, eliminating the need for separate gateway and display components.

What protocols do Monico HMIs support?

They support a wide range of protocols including Modbus (RTU/TCP), Allen Bradley, Siemens, BACnet, SNMP, and more. Each HMI can communicate in up to seven protocols simultaneously across four physical ports (RS-232, RS-485, Ethernet).

What screen sizes are available?

Monico HMIs come in 8-inch, 10-inch, and 15-inch touchscreen models, all featuring full-color graphics and a robust, industrial-grade enclosure.

Can the HMI send alerts or emails?

Yes. Monico HMIs include a built-in SMTP/SMS server that enables email and text alerts for alarms, shutdowns, or critical thresholds — helping you respond to issues faster.

What types of systems can Monico HMIs monitor?

They’re ideal for engine and generator monitoring, including Caterpillar®, J1939/CAN-based engines, and multi-vendor industrial systems. HMIs can also collect data from ancillary sensors such as fuel levels, temperatures, pressures, and more.

How is Monico’s HMI different from other industrial HMIs?

Unlike generic HMIs that require complex integration, Monico HMIs come pre-configured with support for over 400 engine and equipment parameters. They also double as protocol converters, making them a streamlined, all-in-one solution for both data translation and operator visualization.

Can Monico HMIs be used in remote or outdoor environments?

Yes. Monico HMIs are outdoor-rated with UV protection, offer extra-bright backlighting for visibility in sunlight, and are UL 1604 Class I Div II approved for hazardous locations.

Do I need to program the HMI?

No programming is required for standard applications. Each HMI is pre-configured for plug-and-play installation. Field adjustments (e.g., IP addresses, screen tweaks) can be made using Monico’s free MonicoView II™ software.

Can I access the HMI remotely?

Yes. Every HMI includes a built-in web server, allowing remote access to live data and HMI screens from any device with a browser and network access.

Can I use the HMI to control equipment, or is it just for display?

While primarily used for monitoring, Monico HMIs can also trigger digital or analog outputs via optional I/O modules — enabling basic control actions like start/stop commands or alarm acknowledgment.

Is there a solution that combines HMI functionality with advanced edge processing?

Yes. For applications that require analytics, cloud integration, or edge-based control logic, Monico’s mCore® SDR offers a powerful upgrade path — and can be paired with HMIs for complete edge-to-cloud visibility.