WHAT IS MONICOLIVE?

An easy-to-use monitoring platform that seamlessly collects, stores and visualizes data from remote assets

MonicoLive™ is a web-based service that combines our expertise with customer expertise to provide equipment managers with precisely the tools necessary to remotely monitor engines and machines. Preconfigured dashboards provide immediate feedback about the overall health of connected equipment, and dashboards can be accessed from any internet-enabled device with a web browser.

Live-streamed data is retained for historical data review, so you not only get important alerts in real time, but you gain valuable insights on equipment performance, operations, utilization and productivity, and have the tools for diagnostic and forensic event review.

Preconfigured

We’ll set up everything, from hardware to dashboards, so you can access insights immediately

Remote

Live-stream data from connected equipment, wherever it’s located

Visualized

Data is displayed with visual tools that clarify its meaning and enhance insights

KEY FEATURES

Improve productivity, performance and utilization and find out fast when trouble occurs

Alerts & Notifications

You’ll be notified when a condition is met, receive critical alerts via email and text, and get recommended actions

Historical Data Retention

With Monico Live, you can easily go back and review machine/equipment operations, using DVR-like functionality to access the archived data.

Data Visualization

Leverage visualization tools to display data and data relationships in the ways that make sense for you and your equipment

Cloud Analytics

Data trends, correlations and patterns will help you understand what connected equipment is doing and how it’s performing

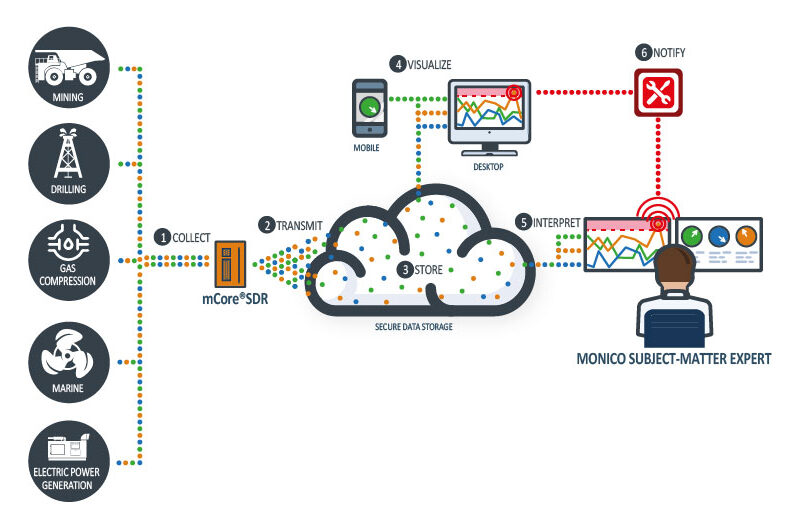

How it Works

OEM-agnostic solution combines powerful data infrastructure with industry-specific expertise

Your Machines. Your Data. Your Way.

Data is collected1 from critical assets (e.g., industrial engines) in the field using mCore®SDR and transmitted2 over ethernet-connected cellular, satellite or local area wired network connection to the MonicoLive™ Solution, hosted in the Microsoft® Azure Cloud, where the data is processed and stored3. End users can log into the MonicoLive™ Web Portal from any browser-enabled device anywhere in the world and interact with the data through dashboards and screen visualizations4 of the data.

A pivotal and often overlooked component to remote monitoring is knowing what data means and knowing what data to watch, analyze and set alerts and notifications for. An added value to MonicoLive™ is the incorporation of Monico’s Subject Matter Experts in helping customers interpret5 the data and get the most out of MonicoLive™ by working with them to understand what their equipment is telling them by building and refining analytics, defining alerts & notifications6, and creating visual tools for understanding the data.

Why Monico

Our Solutions Solve Problems That Other Systems Can’t

Our goal is to fill the gaps and circumvent the barriers that we’ve observed and create solutions that adapt seamlessly to customer needs, regardless of scale or complexity. To this end, we’ve developed MonicoLive for data storage, visualization and cloud analytics, and industry-specific mGuard solutions to provide advanced real-time analytics. We are unique in our ability to fulfill the full spectrum of a customer’s industrial data needs, from the devices that capture machine data through visualization and insights.

20k

Gateways

More than 20,000 of our asset gateways, including mCore SDR, are installed around the world. As manufacturers of our own hardware, we are able to provide extraordinary quality and support.

15+

Technology

Integrations

These include MTU, Cummins, Kohler, Caterpillar, Liebherr, Komatsu, John Deere, Waukesha, Onan, Hitachi, GE and Sandvik, so your solution will be seamless.

20

Countries

Global experience in Europe and Latin America, in addition to the U.S. and Canada, means we can help solve problems at scale while meeting niche local requirements.

1K+

Unique

Businesses

Served

We understand that your organization has its own goals and unique challenges. You can trust that we’ll support you with solutions designed for your industry and objectives.

EASY AS 1,2,3

The Shortest Path to Real-Time

Actionable Intelligence™

1

Schedule a Demo

We’ll walk you through the process and share examples grounded in real data. No big sales pitch. We’ll discuss the problems you’re trying to solve, identify your needs and address your questions about ROI, security, the implementation process, and more.

2

Let Us Configure Your Solution

We won’t just sell you a gateway and wish you luck. Our powerful solutions are simplified for each customer by being pre-configured, down to the serial number of each asset. You’ll easily access data and gain insights from day one, without struggling with siloed data or differing protocols.

3

Count On Us for Support

Our job isn’t done until implementation is successful and you’re getting data exactly the way you want it, where you want it. We’ll provide installation, training and support. In addition, our online resource library is available 24/7.

FAQs

Frequently Asked Questions

What kind of equipment can MonicoLive™ monitor?

MonicoLive™ is designed to monitor high-horsepower engines, generators, compressors, and other critical industrial assets — particularly in demanding environments such as oil & gas, mining, marine, and power generation.

What insights can I gain from using MonicoLive™?

You’ll have access to key metrics such as equipment performance, utilization, productivity, and operational health. You can also review historical data for trend analysis, diagnostics, and forensic event investigations.

Can I access MonicoLive™ from anywhere?

Yes. As a browser-based solution, MonicoLive™ can be accessed from any internet-enabled device, whether you’re in the control room, in the field, or working remotely.

Can MonicoLive™ integrate with third-party systems?

Yes. MonicoLive™ leverages the AVEVA PI System — the same industrial data infrastructure trusted by over 250 Fortune 500 companies — delivering scalable, high-performance data processing and storage without the complexity of managing it yourself. Integration with these industrial data ecosystems, ensures compatibility with your broader data strategy.

How does the system collect and transmit data?

Data is collected at the edge using Monico’s mCore®SDR, then securely transmitted over Ethernet, cellular, satellite, or wired networks to the MonicoLive™ platform hosted in Microsoft® Azure. The data is then processed, stored, and visualized through browser-accessible dashboards.

What kind of visualizations are available?

MonicoLive™ includes flexible, pre-configured dashboards that use bar charts, line graphs, gauges, and other tools to help you interpret your equipment’s performance. Visualizations can be customized to suit your specific monitoring needs.

Does MonicoLive™ support alerts and notifications?

Absolutely. You can configure alerts based on critical conditions, receive notifications via email or text, and track recommended actions and acknowledgments. Monico’s team can help define alert criteria specific to your equipment and use case.

Does it support analytics and trend detection?

Yes. MonicoLive™ enables users to identify trends, correlations, and performance patterns to support predictive maintenance and smarter decision-making. Our engineers work directly with customers to build meaningful analytics based on your equipment’s behavior.