WHAT IS MGUARD® MACHINEWATCH™?

An advanced machine health analytics tool that’s always on duty

Specifically designed for the mining industry, mGuard® MachineWatch™ provides remote condition monitoring and predictive analytics for critical equipment. Our engineers configure the system for you, to your exact hardware requirements, so that data is collected, time-stamped, aggregated, cleansed, translated, buffered and transmitted in an instant, via our MonicoLive™ servers.

Real-time predictive analytics run unattended 24/7/365 as data streams in from mobile, field or ancillary assets. mGuard® MachineWatch™ eliminates the need to run analytics manually by downloading data records, CAN logs or other information into spreadsheets or other tools.

Preconfigured

We’ll set up everything, from hardware to dashboards, you can access insights immediately

24/7/365

Real-time data and analytics run around the clock, with no human interaction needed

Historical Data

Archived data is easily accessible and viewable with DVR-like functionality

KEY FEATURES

Improve the productivity, performance, utilization & safety of mining machines

mGuard® MachineWatch™ provides service managers, technicians and maintenance crews with a powerful remote monitoring tool that is specifically designed to provide valuable insight into the performance and health status of mine assets. It gives you the power to improve condition-based maintenance and take a proactive approach that can enhance productivity and help you plan scheduled maintenance intervals that make it less likely you’ll have to pay for after-hours labor and expedited parts.

Because we preconfigure the solution for you, you’ll rapidly achieve ROI and see the operational benefits. The impact of mGuard® MachineWatch™ can include:

- Fewer unnecessary and/or unscheduled repairs

- Increased productivity and less unscheduled downtime

- More time to schedule and prepare for needed repairs

- Avoiding failure mode misdiagnosis and the associated additional costs

- Useful analysis that aids in determining the severity of a failure

- Improved Mean Time To Repair (MTTR)

- Improved reliability, utilization and Mean Time Between Outages (MBTO)

Furthermore, by alerting you to any potential conditions that could result in an unplanned shutdown event or a catastrophic failure, mGuard® MachineWatch™ can help you avert these costly, potentially hazardous problems.

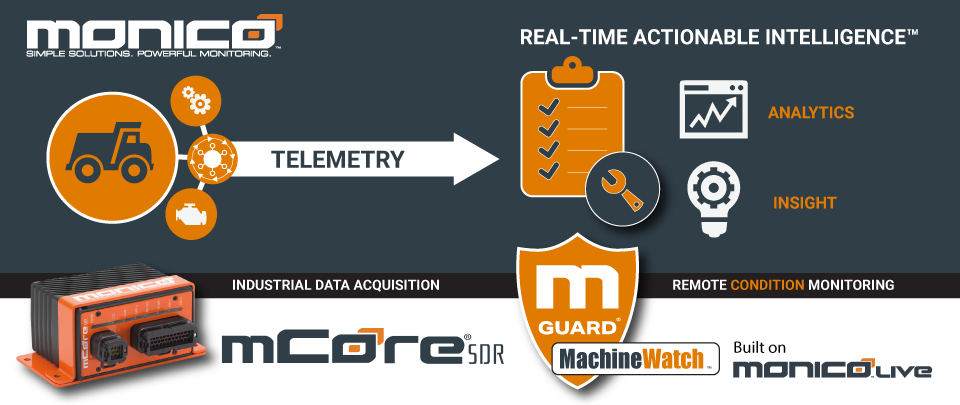

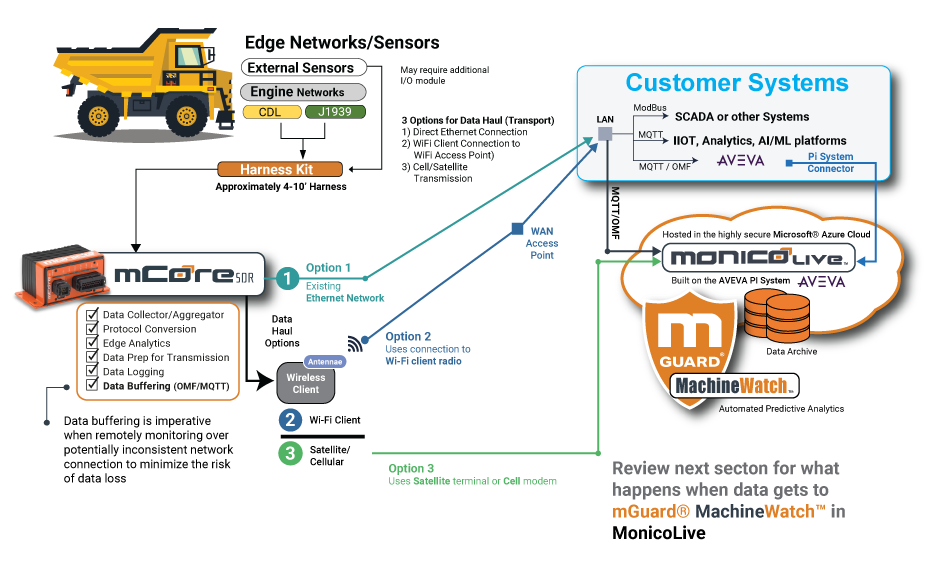

How Does mGuard® MachineWatch™ Fit Into Your Telemetry Strategy?

Monico’s integrated approach with mCore®SDR and mGuard MachineWatch™ streamlines your entire telemetry stack—so you can focus on uptime, not infrastructure.

Discover how we help you:

- Collect high-frequency data from mixed OEM fleets—securely and reliably

- Analyze conditions in real-time using 50,000+ prebuilt algorithms

- Visualize key metrics with intuitive dashboards built for operations teams

- Respond faster with automated alerting and alarm management tools

How it Works?

An integrated system analyzes gigabytes of data in a matter of milliseconds

Your Machines. Your Data. Your Way.

mGuard® MachineWatch™ collects real-time streaming data from mining assets outfitted with the mCore®SDR industrial data acquisition device. No expensive sensor add-on packages are required.

Data then flows into the trusted MonicoLive™ platform, where mGuard® MachineWatch™ analytics go to work instantly. Our automated analyses and notifications are completely set up and managed by our subject matter experts to help you save money and optimize operations through improved asset reliability, reduced unscheduled shutdowns and improved preventative maintenance planning.

MachineWatch can analyze:

- Engines and components

- Hydraulic systems and components

- Drive systems and components

- Chassis and components

- Cooling systems

- Air intake systems

- Lubrication systems

- Equipment KPIs

ADVANCED FEATURES

Powerful industrial data analysis alerts you to trouble

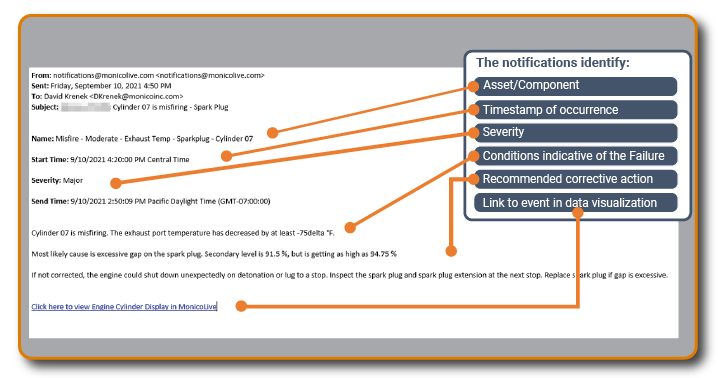

Automated Advanced Notifications & Alerts

When MachineWatch™ identifies a potential failure or shutdown, the system will trigger an email notification. These notifications provide the name of the asset, time of occurrence, severity, the types of conditions that are indicative of a failure, recommended action and a link to MonicoLive. This makes it easy to look at the data coming in from the asset and get to the root of the problem quickly.

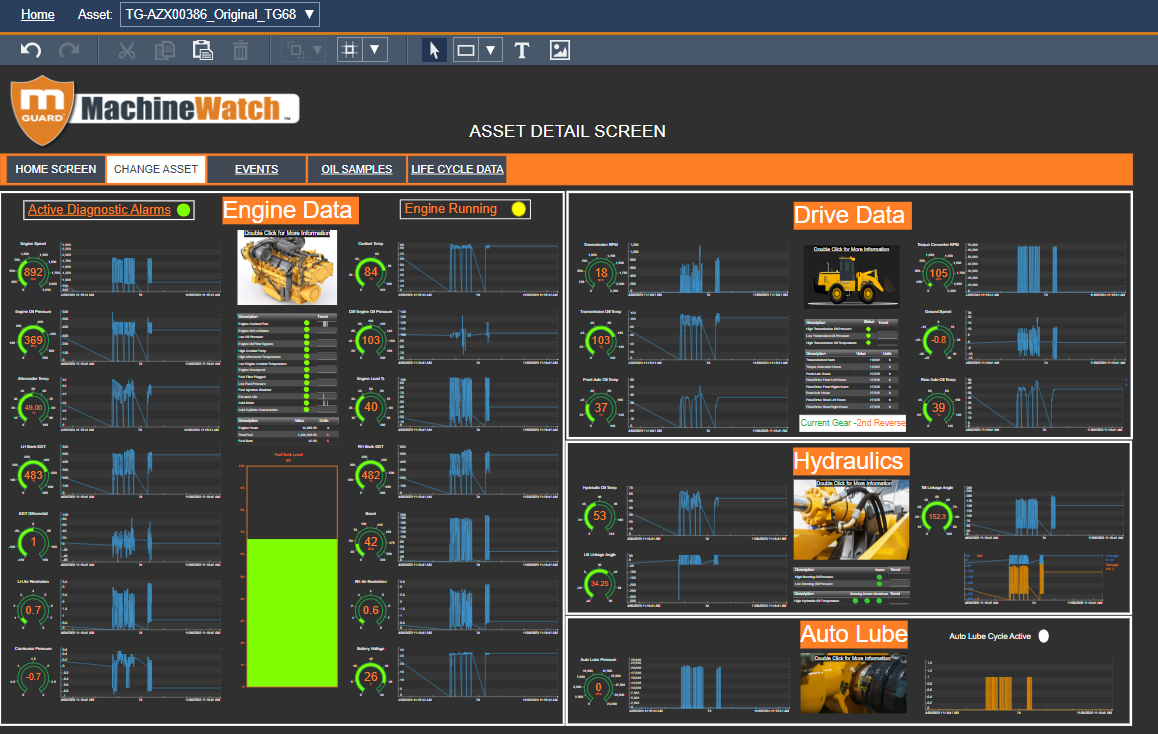

Dashboards/Data Visualization & Alerts

A key feature of mGuard® MachineWatch™ is the data visualization environment. Built within MonicoLive, MachineWatch™ provides a full suite of data visualization screens called dashboards. All dashboards are preconfigured and set up for the specific asset.

In addition to viewing current data, you can look at historical data with simple functionality that lets you move backwards and forwards along the timeline or select a specific date/time. Dashboards include:

- Asset Overview

- Engine

- Intake

- Exhaust

- Drive

- Chassis

- Hydraulic Systems

- Grease System

- Oil Analysis Detail

- Component Life Tracking

- Event & Diagnostic Codes

Fluids Analysis

Fluids analysis dashboards are included in the data visualization capabilities. mGuard® MachineWatch™ brings together what had previously been disparate silos of machine health data that required substantial and highly expert human analysis: machine telemetry and analysis of fluids like engine oil, transmission fluids and hydraulic fluids. MachineWatch MDEs (Monico Defined Events) consider both fluid analysis and telemetry data in combination, to better predict failure at the earliest onset. This advanced feature saves the time needed to review the oil analysis reports and corresponding telemetry data, a task that requires hard-to-find people with the necessary skill sets, experience and knowledge across multiple machine types and different OEMs.

EASY AS 1,2,3

The Shortest Path to Real-Time

Actionable Intelligence™

1

Schedule a Demo

We’ll walk you through the process and share examples grounded in real data. No big sales pitch. We’ll discuss the problems you’re trying to solve, identify your needs and address your questions about ROI, security, the implementation process, and more.

2

Let Us Configure Your Solution

We won’t just sell you a gateway and wish you luck. Our powerful solutions are simplified for each customer by being pre-configured, down to the serial number of each asset. You’ll easily access data and gain insights from day one, without struggling with siloed data or differing protocols.

3

Count On Us for Support

Our job isn’t done until implementation is successful and you’re getting data exactly the way you want it, where you want it. We’ll provide installation, training and support. In addition, our online resource library is available 24/7.

Why Monico

Our Solutions Solve Problems That Other Systems Can’t

Our goal is to fill the gaps and circumvent the barriers that we’ve observed and create solutions that adapt seamlessly to customer needs, regardless of scale or complexity. To this end, we’ve developed MonicoLive for data storage, visualization and cloud analytics, and industry-specific mGuard solutions to provide advanced real-time analytics. We are unique in our ability to fulfill the full spectrum of a customer’s industrial data needs, from the devices that capture machine data through visualization and insights.

20k

Gateways

More than 20,000 of our asset gateways, including mCore SDR, are installed around the world. As manufacturers of our own hardware, we are able to provide extraordinary quality and support.

15+

Technology

Integrations

These include MTU, Cummins, Kohler, Caterpillar, Liebherr, Komatsu, John Deere, Waukesha, Onan, Hitachi, GE and Sandvik, so your solution will be seamless.

20

Countries

Global experience in Europe and Latin America, in addition to the U.S. and Canada, means we can help solve problems at scale while meeting niche local requirements.

1K+

Unique

Businesses

Served

We understand that your organization has its own goals and unique challenges. You can trust that we’ll support you with solutions designed for your industry and objectives.

FAQs

Frequently Asked Questions

What is mGuard® MachineWatch™?

mGuard® MachineWatch™ is a real-time remote condition monitoring and predictive analytics platform designed specifically for the mining industry. It continuously monitors and analyzes health and performance data from mobile and fixed mining assets to help prevent equipment failure and improve operational efficiency.

Is MachineWatch™ difficult to set up?

No. Monico delivers mGuard® MachineWatch™ fully preconfigured—including hardware, data acquisition, and dashboards. There’s no need for in-house setup, and users can start accessing insights immediately after deployment.

Does MachineWatch™ require special sensors or aftermarket hardware?

No. MachineWatch™ works with your existing asset sensors through Monico’s mCore®SDR device. No expensive add-on sensor packages are required, making implementation faster and more cost-effective.

How are alerts and notifications delivered?

When MachineWatch™ detects conditions that may indicate a failure, it sends automated email notifications with asset details, severity level, condition type, recommended actions, and a direct link to MonicoLive™ for deeper analysis.

Which mining equipment does MachineWatch™ monitor?

MachineWatch™ analyzes a wide range of systems and components including engines, hydraulic systems, cooling systems, drive systems, chassis, lubrication systems, air intake, and other critical equipment KPIs. It also integrates fluid analysis (like engine oil or hydraulic fluids) with telemetry data for deeper insights.

How does MachineWatch™ help prevent unplanned downtime?

MachineWatch™ uses real-time data and advanced predictive analytics to detect potential equipment failures early—before they lead to unexpected breakdowns. Automated alerts allow maintenance teams to respond proactively, minimizing unplanned shutdowns and optimizing repair scheduling.

Can I access historical machine data with MachineWatch™?

Yes. mGuard® MachineWatch™ includes DVR-like data navigation within the MonicoLive™ platform, allowing users to scroll back through past data, isolate trends, and investigate failure events.

How does MachineWatch™ support condition-based maintenance?

By continuously analyzing real-time performance data, MachineWatch™ enables a proactive, condition-based maintenance strategy. It helps teams identify early warning signs of wear or degradation, improving asset reliability and reducing maintenance costs.