WHAT IS MGUARD® COMPRESSORWATCH™?

Advanced analytics running 24/7/365

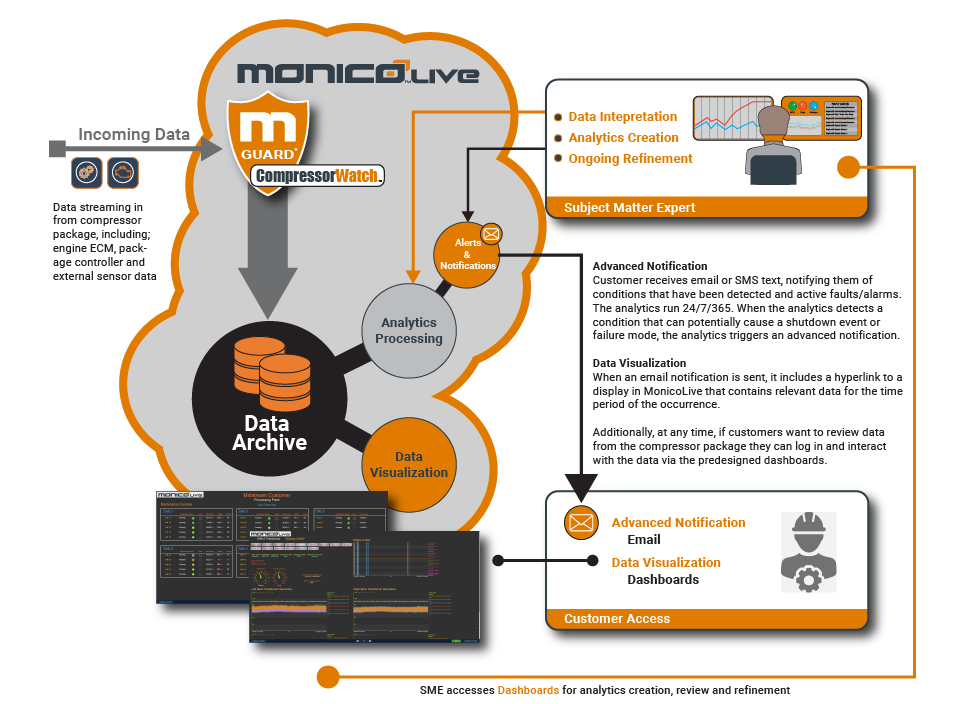

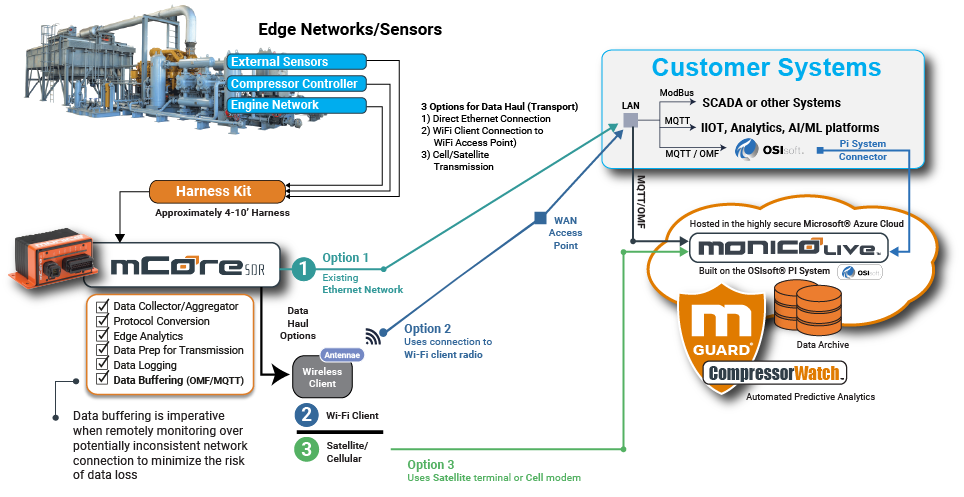

Specifically designed for reciprocating gas compressors, mGuard® CompressorWatch™ provides remote condition monitoring and predictive analytics for compression station packages. Our engineers configure everything for you, to your exact hardware requirements, so that data is collected, time-stamped, aggregated, cleansed, translated, buffered and transmitted in an instant to our MonicoLive™ servers.

As data streams in from stations, engines and compressors, real-time predictive analytics run unattended 24/7/365. mGuard® CompressorWatch™ eliminates the need to run analytics manually by downloading data records, CAN logs or other information into cumbersome spreadsheets or other tools.

Preconfigured

We’ll set up everything, from hardware to dashboards, so you can access insights immediately

24/7/365

Real-time data and analytics run around the clock, with no human interaction needed

Historical Data

Archived data is easily accessible and viewable with DVR-like functionality

KEY BENEFITS

Optimizing the performance, uptime & reliability of compressors and ancillary equipment

mGuard® CompressorWatch™ provides the oil and gas industry with a powerful remote monitoring tool that is specifically designed to provide valuable insight into the performance and health status of reciprocating gas compressors. mGuard® CompressorWatch™ can detect when components might still be healthy but are beginning to deteriorate. You’ll be alerted, so that action can be taken before deterioration results in failure.

Because we preconfigure the solution for you, you’ll rapidly achieve ROI and see the operational benefits of being able to detect end of useful life and reliability-related failures. The impact of mGuard® CompressorWatch™ can include:

- Increased productivity and less unscheduled downtime

- More time to schedule and prepare for needed repairs

- Fewer unnecessary and/or unscheduled repairs

- Improved Mean Time To Repair (MTTR)

- Avoiding failure mode misdiagnosis and the associated additional costs

- Useful analysis that aids in determining the severity of a failure

- Improved reliability, utilization and Mean Time Between Outages (MBTO)

How it Works?

Analyzing gigabytes of data in a matter of milliseconds

Your Machines. Your Data. Your Way.

mGuard® CompressorWatch™ collects real-time streaming data from compressors and ancillary equipment outfitted with the mCore®SDR industrial data acquisition device. Data flows into the trusted MonicoLive™ platform, where mGuard® CompressorWatch™ analytics go to work instantly. No expensive sensor add-on packages are required.

Our automated analyses and notifications have been painstakingly developed and refined by our subject matter experts to help you save money and optimize operations through improved asset reliability, reduced unscheduled shutdowns and improved preventative maintenance planning. Assets that CompressorWatch™ is designed to analyze include:

- Engines and compressor components

- Engine and compressor sensors

- Emissions

- Jacket water cooling systems

- Auxiliary cooling systems

- Lubrication

- Exhaust systems

- Equipment KPIs

- Air intake systems

- Engine performance

- Compressor valve failures

- Ignition systems

- Air/fuel ratio systems

ADVANCED FEATURES

Powerful compressor data analysis alerts you to trouble

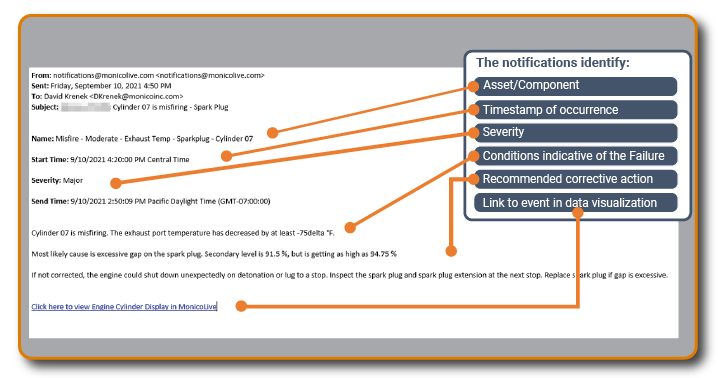

Automated Advanced Notifications & Alerts

When CompressorWatch™ identifies a potential failure or shutdown, the system will trigger an immediate notification and a direct link to MonicoLive. This makes it easy to get to the root of the problem quickly and perform additional human analysis of the data.

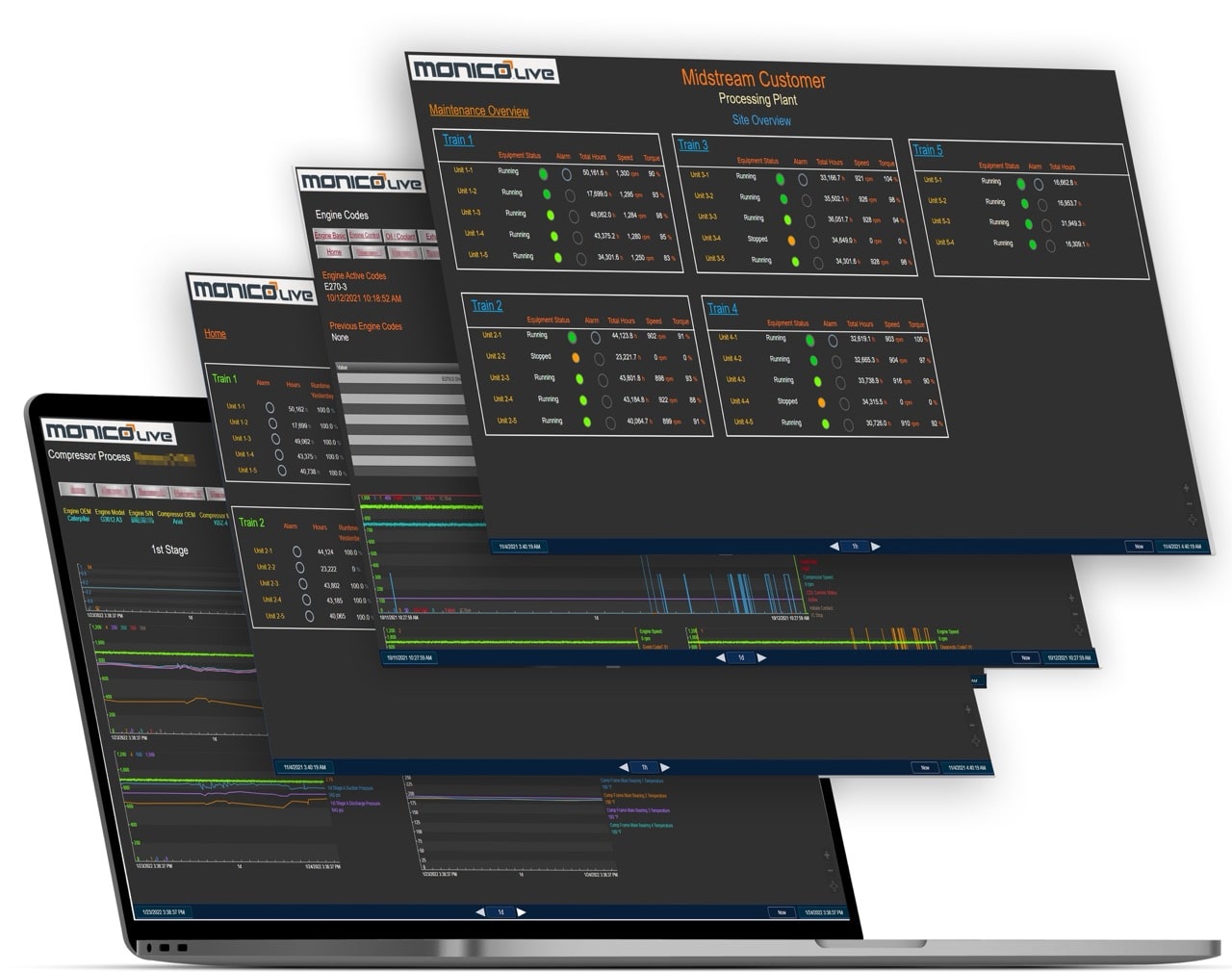

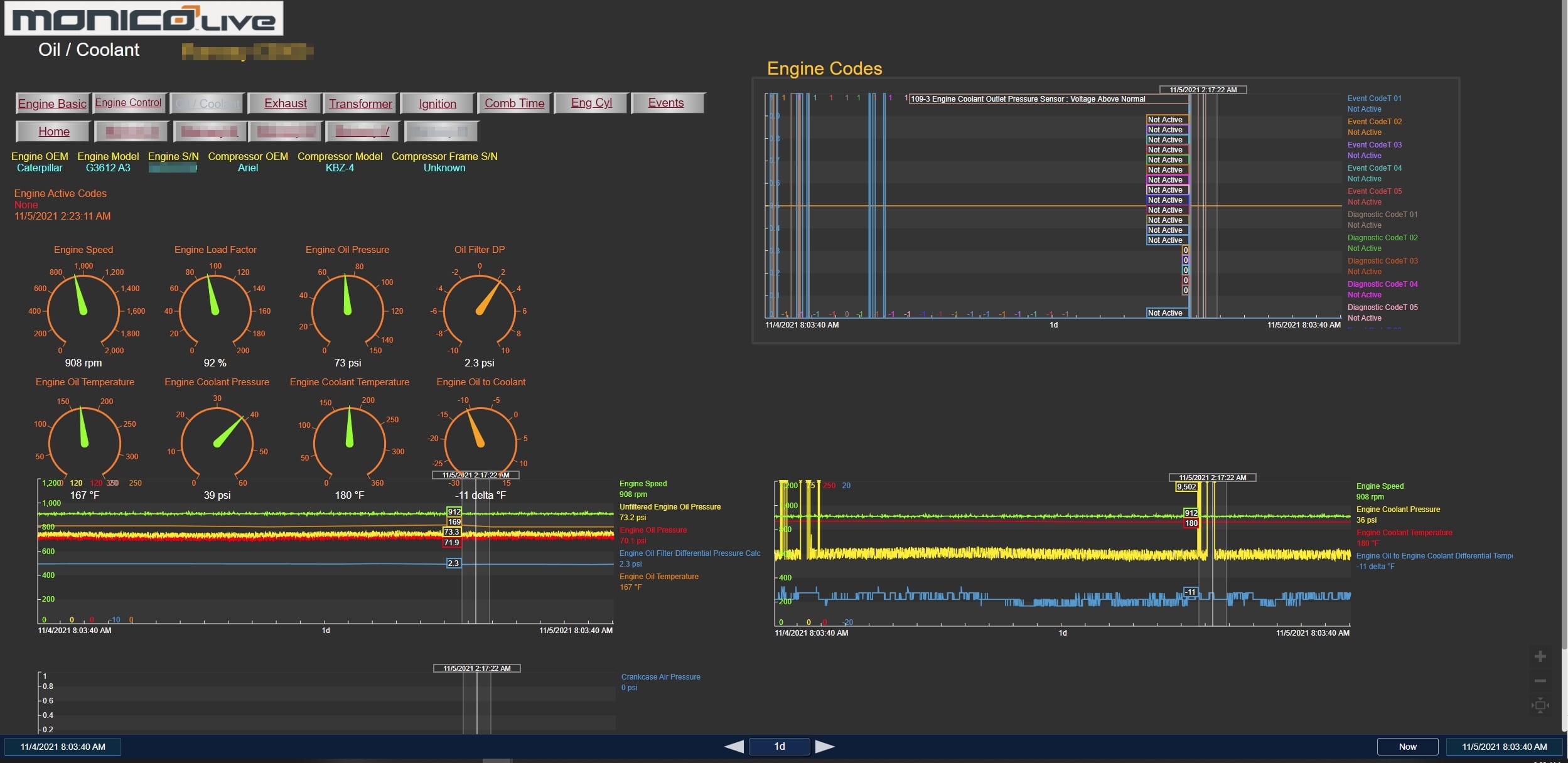

Dashboards/Data Visualization

The data visualization environment is a key feature of mGuard® CompressorWatch™. Built within MonicoLive, the dashboards are preconfigured and set up for each specific asset. In addition to viewing current data, you can look at historical data with simple functionality that lets you move backwards and forwards along the timeline or select a specific date/time. Dashboards include:

- Event & Diagnostic Codes

- Status

- A/F Ratio & Load Control

- Oil-Coolant Systems

- Exhaust Temperatures

- Transformer Secondary

- Ignition Timing

- Combustion Time

- Engine Cylinder Data

EASY AS 1,2,3

The Shortest Path to Real-Time

Actionable Intelligence™

1

Schedule a Demo

We’ll walk you through the process and share examples grounded in real data. No big sales pitch. We’ll discuss the problems you’re trying to solve, identify your needs and address your questions about ROI, security, the implementation process, and more.

2

Let Us Configure Your Solution

We won’t just sell you a gateway and wish you luck. Our powerful solutions are simplified for each customer by being pre-configured, down to the serial number of each asset. You’ll easily access data and gain insights from day one, without struggling with siloed data or differing protocols.

3

Count On Us for Support

Our job isn’t done until implementation is successful and you’re getting data exactly the way you want it, where you want it. We’ll provide installation, training and support. In addition, our online resource library is available 24/7.

Why Monico

Our Solutions Solve Problems That Other Systems Can’t

Our goal is to fill the gaps and circumvent the barriers that we’ve observed and create solutions that adapt seamlessly to customer needs, regardless of scale or complexity. To this end, we’ve developed MonicoLive™ for data storage, visualization and cloud analytics, and industry-specific mGuard® solutions to provide advanced real-time analytics. We are unique in our ability to fulfill the full spectrum of a customer’s industrial data needs, from the devices that capture machine data through visualization and insights.

20k

Gateways

More than 20,000 of our asset gateways, including mCore SDR, are installed around the world. As manufacturers of our own hardware, we are able to provide extraordinary quality and support.

15+

Technology

Integrations

These include MTU, Cummins, Kohler, Caterpillar, Liebherr, Komatsu, John Deere, Waukesha, Onan, Hitachi, GE and Sandvik, so your solution will be seamless.

20

Countries

Global experience in Europe and Latin America, in addition to the U.S. and Canada, means we can help solve problems at scale while meeting niche local requirements.

1K+

Unique

Businesses

Served

We understand that your organization has its own goals and unique challenges. You can trust that we’ll support you with solutions designed for your industry and objectives.

FAQs

Frequently Asked Questions

What is mGuard® CompressorWatch™?

mGuard® CompressorWatch™ is a remote monitoring and real-time predictive analytics solution designed specifically for reciprocating gas compressors. It continuously collects, processes, and analyzes compressor data 24/7/365 to help operators detect potential issues before they lead to failures.

What types of equipment does CompressorWatch™ monitor?

mGuard® CompressorWatch™ monitors engines, compressors, and ancillary systems including emissions, lubrication, jacket water cooling, air/fuel ratio systems, exhaust, ignition systems, and more — all without requiring additional sensors.

Is historical compressor data accessible with CompressorWatch™?

Yes. All compressor and engine data is archived and easily viewable through MonicoLive’s timeline-based interface, allowing users to scroll back in time and investigate performance trends or failure precursors.

What makes CompressorWatch™ different from traditional compressor monitoring systems?

Unlike traditional methods that require manual downloads and spreadsheet analysis, CompressorWatch™ provides real-time analytics without human intervention. It leverages Monico’s proprietary mCore®SDR and MonicoLive™ platform to deliver industrial-grade reliability and predictive accuracy.

How does mGuard® CompressorWatch™ improve compressor reliability?

By running unattended predictive analytics in real-time, CompressorWatch™ can detect early signs of component degradation. This allows maintenance teams to act proactively, reducing unscheduled downtime and avoiding costly misdiagnoses or unnecessary repairs.

Do I need to manually configure CompressorWatch™?

No. Monico handles all system configuration — from hardware installation to dashboard setup. CompressorWatch™ is delivered preconfigured for your specific compressor assets, so you can start gaining insights immediately.

How are alerts and notifications delivered?

Automated alerts are triggered when the system detects abnormal conditions or potential failures. Each alert includes a direct link to the MonicoLive™ dashboard for further root cause analysis and visualization.

Can CompressorWatch™ help with preventative maintenance planning?

Yes. The system’s advanced analytics identify patterns and trends in equipment performance, enabling more accurate maintenance planning and reducing unnecessary service events.