WHAT IS mCore?

mCore® SDR: Our flagship data acquisition platform

The mCore®SDR is our flagship, next-generation data acquisition platform. While we’ve designed the device for complex systems, we’ve also ensured that it comes as close as possible to “plug and play” for our customers.

Purpose-built for industrial IoT (IIoT), remote monitoring, telematics applications and edge analytics, the device supports multiple protocols, and is designed to simultaneously ingest and transmit data at high velocity from multiple sources.

Designed For:

- Industrial IoT (IIoT) monitoring and connectivity (support for OMF and MQTT)

- Acquiring and integrating industrial asset data into AVEVA® PI

- Acquiring and integrating industrial asset data into IIoT Solutions via MQTT

- Industrial cybersecurity (leverages SSL/TLS, data encryption and security certificates)

- Data buffering of OMF and MQTT

- Withstanding harsh environments in a rugged package (IP 66 and IP67 rated / Class I Div II certified)

- Maximum computing power, speed and efficiency

Provides:

- Industrial protocol translation

- Secure edge data collection and data transmission

- Increased confidence of data capture integrity

- Edge analytics computing platform and processing power, capable of 7 billion calculations per second

mCore®SDR user interface tools are hosted on the device

End users can access the user interface from any computer with an ethernet connection to the mCore®SDR. No software installation is required. We ship the device to you preconfigured for your application.

- View live data

- Manage multiple level password access

- Extract data logs

- Manage system functions

- Onboard network troubleshooting tools

- Setup

- Protocols

- Firewall

- Define Data Tags

- Configure Web Server

- Data Logs

mCore® SDR creates a powerful native interface between your machines and critical applications that require real-time information

We developed mCore® SDR with three pillars in mind:

- Maximum computing power, speed and efficiency

- Industrial cybersecurity

- The ability to withstand harsh environments, whether in a factory or on mobile equipment. Benefits of the device include:

- Providing a new source of information from industrial assets that could not previously be monitored

- Minimal equipment requirements, with no need for multiple protocol convertors or rugged laptops for data collection

- No programming or configuration required (preconfigured)

- Data buffering that ensures reliable capture of data over inconsistent wireless networks (important for analytics, AI, ML applications based on data)

- Increased visibility into equipment productivity

- Improved service/maintenance, reliability and uptime, thanks to added visibility into operating parameters during remote condition monitoring

- Ability to run analytics on Operations and Production data from connected asset

- Ability to run proprietary/confidential customer code for applications in container at the edge

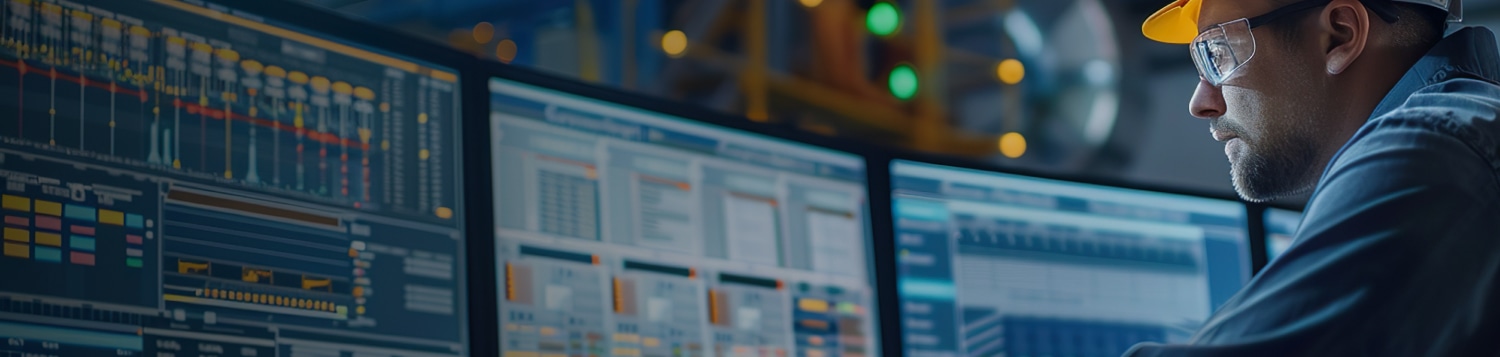

How mCore Works with MonicoLive™

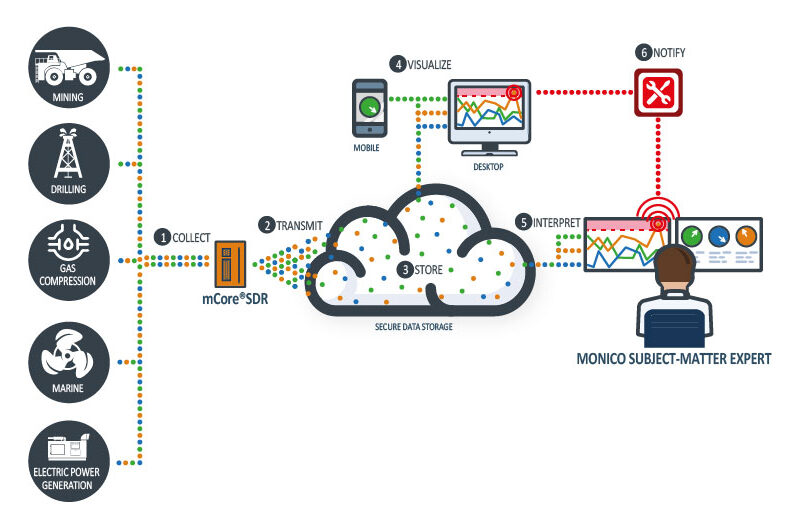

From the Edge to the Cloud: Real-Time Intelligence with MonicoLive™

Data is collected1 from critical assets (e.g., industrial engines) in the field using mCore®SDR and transmitted2 over ethernet-connected cellular, satellite or local area wired network connection to the MonicoLive™ Solution, hosted in the Microsoft® Azure Cloud, where the data is processed and stored3. End users can log into the MonicoLive™ Web Portal from any browser-enabled device anywhere in the world and interact with the data through dashboards and screen visualizations4 of the data.

A pivotal and often overlooked component to remote IoT monitoring is knowing what data means and knowing what data to watch, analyze and set alerts and notifications for. An added value to MonicoLive™ is the incorporation of Monico’s Subject Matter Experts in helping customers interpret5 the data and get the most out of MonicoLive™ by working with them to understand what their equipment is telling them by building and refining analytics, defining alerts & notifications6, and creating visual tools for understanding the data.

Why Monico

What sets this next-generation platform apart

Preconfigured For Your Assets

Before shipping the device to you, Monico configures the gateway to the specific asset that it will be connected to and maps all the data tags. Simply connect power to the mCore®SDR and a source of internet access and data will begin flowing.

Real-Time Streaming Data

Real-time streaming data from industrial assets (mobile machines, engines, gensets, compressors, etc.), including Caterpillar® Data Link (CDL) Protocol Support, S.A.E J1939 (CDL) Protocol Support and more. Multiple simultaneous outputs and multiple simultaneous inputs: (2) CAN ports, (1) CDL, (2) Ethernet, (1) RS232, (1) RS485.

Data Integration

These capabilities include support for data integration with cloud services platforms and Industrial IoT platforms (via MQTT) and simple Integration with existing AVEVA PI data infrastructure. PI archive data tag assignments are taken care of for you.

Data Buffering

The device provides onboard data buffering of OMF and MQTT data. This is imperative to reduce the risk of data loss in remote monitoring or when network connections are inconsistent.

EASY AS 1,2,3

The Shortest Path to Real-Time

Actionable Intelligence™

1

Schedule a Demo

We’ll walk you through the process and share examples grounded in real data. No big sales pitch. We’ll discuss the problems you’re trying to solve, identify your needs and address your questions about ROI, security, the implementation process, and more.

2

Let Us Configure Your Solution

We won’t just sell you a gateway and wish you luck. Our powerful solutions are simplified for each customer by being pre-configured, down to the serial number of each asset. You’ll easily access data and gain insights from day one, without struggling with siloed data or differing protocols.

3

Count On Us for Support

Our job isn’t done until implementation is successful and you’re getting data exactly the way you want it, where you want it. We’ll provide installation, training and support. In addition, our online resource library is available 24/7.

FAQs

Frequently Asked Questions

What is mCore® SDR?

mCore® SDR is Monico’s next-generation edge computing platform that combines data acquisition, protocol conversion, real-time analytics, I/O integration, and cloud connectivity into one powerful device. It’s built to modernize industrial asset monitoring from the edge to the cloud.

How is mCore® different from Monico’s traditional gateways?

While Monico gateways focus on protocol conversion and equipment communication, mCore® adds local logic processing, alarm handling, data buffering, cloud integration, and custom analytics — reducing latency and enhancing system intelligence.

Can mCore® connect to cloud platforms?

Yes. mCore® is cloud-ready with native support for MonicoLive™, MQTT brokers, and other platforms like Azure or AWS IoT. It’s built for edge-to-cloud architectures.

Does mCore® support local I/O?

Yes. mCore® includes or supports expansion modules for:

- RTDs and Thermocouples

This allows users to directly monitor field signals and control equipment. - Digital Inputs/Outputs

- Analog Inputs/Outputs (0–10V, 0–20mA)

What kind of analytics can mCore® perform?

mCore® can execute threshold monitoring, trending, statistical analysis, and conditional logic at the edge. This enables predictive maintenance workflows and faster response to abnormal conditions.

What does “SDR” stand for?

SDR stands for Smart Data Router, highlighting the product’s role in collecting, processing, and routing equipment data between field devices, control systems, and remote platforms.

What protocols does mCore® support?

mCore® supports 100+ industrial protocols, including:

- CDL, J1939, BACnet, DNP3, and more

- It can run multiple protocols simultaneously, making it ideal for mixed-architecture systems.

- Modbus RTU/TCP

- EtherNet/IP (Allen Bradley)

- OPC UA

- MQTT (for cloud)

What types of equipment can mCore® monitor?

It’s compatible with a wide range of industrial engines, gensets, compressors, pumps, and process systems — especially in sectors like oil & gas, power generation, marine, and heavy equipment.

Can I run custom logic or alarms on the device?

Absolutely. mCore® includes an embedded logic engine that lets you configure alarm conditions, output triggers, data transformations, and event-based actions, reducing the need for PLC-side programming.

Is mCore® secure and reliable for remote use?

Yes. It features secure data handling, event buffering in case of network loss, and remote provisioning tools, all housed in a rugged, industrial-grade enclosure built for harsh environments.

Who is mCore® best suited for?

mCore® is ideal for:

- Industrial teams connecting edge assets to cloud platforms

- OEMs building smarter machines

- Operators modernizing legacy infrastructure

- Integrators deploying condition monitoring and predictive maintenance solutions